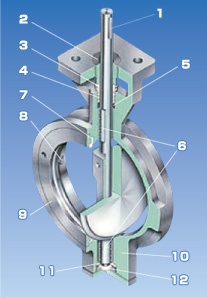

B SERIES

Double eccentric structure, facilitating lightweight, compact form and easy maintenance. This is BF Kogyo’s leading product featuring excellent operability and durability.

[Casting Products]

This is a highly innovative valve that achieves both robustness and lightness. It has a double eccentric structure enabling total tightness and low torque. This facilitates greater operability, longer seat life and a major decrease in maintenance as well as high cost performance. It is used in various industries including the chemical, nuclear power, steelmaking and air conditioning sectors.

- Key way

It allows easy assembly and disassembly of all types of actuator - Gland follower

- Packing gland

- Gland packing

- Adapter

- Upper and lower bearings

The bearings are of Teflon coated stainless steel mesh construction to ensure smooth and reliable shaft movement with balanced contact between disc and seat resulting in lower torque. - Seat

- Disc stopper

- Seat retainer

Integral with retainer plate. Plate is located by. - Body

Slim wafer pattern for easy mounting between flanges to specification - Thrust ring

- Thrust piece

● Standard specifications

| Size | 80A~300A |

|---|---|

| Working pressure | MAX 1.0MPa |

| Flanges | JIS、ANSI |

● Standard materials(JIS code)

| Body | FCD450-10、SCS13、SCS14、SCS16 |

|---|---|

| Disc | FCD450-10、SCS13、SCS14、SCS16 |

| Shaft | SUS304、SUS316、SUS316L |

※The materials of the body, disc and shaft can be chosen freely as required.

● Standard test pressure(hydraulic pressure)

| Body shell | 1.5MPa |

|---|---|

| Seat | 1.1 MPa |

● Seat materials

| NBR | -10 ~80℃ |

|---|---|

| EPDM | -10 ~120℃ |

| FKM | -10 ~150℃ |

| PTFE | -20 ~180℃ |

| METAL | -20 ~200℃ |